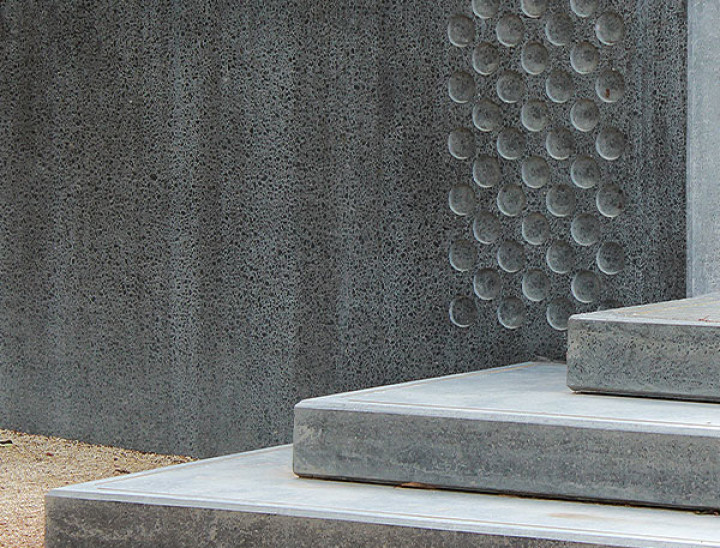

One of the beautiful thing about monarc for Architects and Designers is the creative freedom that Monarc provides.

With its multiple diamond toolings, Monarc provides unlimited design potential breaking beyond the barriers of catalogued product selection.

In order to create a bespoke design it must first be understood how the process of creation and production takes place.

- First Concrete colours must be selected, Panels may be cast with the colour full thickness or could adopt a minimum 40mm facing layer (additional thickness to any structural thickness requirements)

Precast panels are cast intended for further monarc processing as such adopt unique and critical casting methodologies to deliver an incomparable aesthetic appearance. - Following the Casting and minimum curing time, (honing : 5 days, Brushing : 2 days, Hammering : 10 days) areas of panel coverage need to be defined and surface textured, This involves first Grinding back into the aggregate (apx. 3mm) then refining the defined area with the selected finishes or an F5 raw as-cast surface.

- NB i - Precast panels are cast 5mm over thickness to accommodate the surface texture refinement while retaining the minimum structural thickness specified.

- NB ii - Monarc's texture processing heads are 600mm in diameter and require a minimum area of 500mm wide, Smaller areas would require hand processing which can result in a difference in appearance.

- Following Surface Texturing Decorative Cuts, Mills, Routing or various combinations can be processed into the panel face.

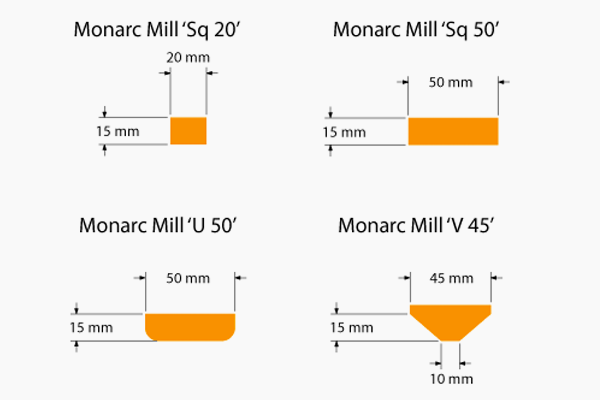

Monarc Milling tools

Maximum Milling Depth is 15mm - This has proven to provide excellent contrast through natural light reflection & shadow.

Monarc's milling wheels can process Straight lines to any angle.

(curves can only be accomplished through casting in rebates or routing to a path)

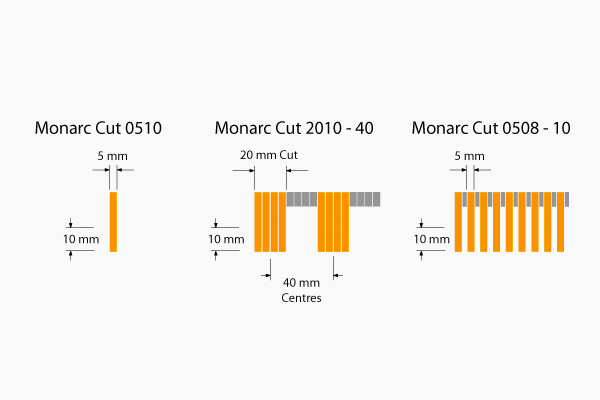

Monarc Cutting tools

- Cutting blades are 300mm +/- Diameter (NB. As the cut blade radius is 150mm, Cut formed rebates within the panel area will reflect the radiused entry and exit variable by the depth of the cut)

- 5mm +/- cutting width

- Maximum Cut depth is 15mm

- Blades me ganged together to create Thicker Cuts resulting in a ribbed cut texture within the cut rebate (maximum 30mm Ganged Cut width)

- Multiple blades may be spaced apart in a single cut pass using spacer plates, Maximum stacked tool width: 100mm wide.

- Monarc's cutting blades can process straight lines to any angle (curves can only be accomplished through casting in rebates or routing to a path). Examples of Blade configuration:

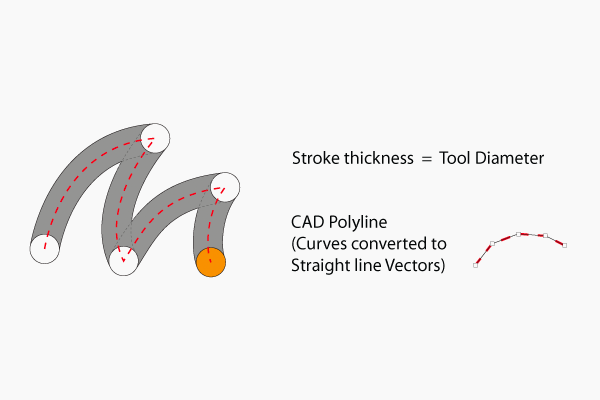

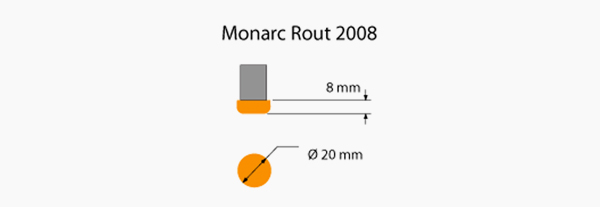

Monarc Routing tools

- Routing concrete is a slow process consisting of a spinning Diamond 'Candle' head tool'

- Tools follow a stroke centre path line generated via CAD Polyline data

- Curves are converted to straight vector paths

- Blocks of removal are processed with repeat strokes over lapped to carve out the selected area.

Note that Strokes and external corners end to the tool radius.

Available profiles include:

"Design is limited only to the extent of your own imagination ... "